Making AirHandling Units More Efficient with Demand Control Ventilation and Occupancy Sensors

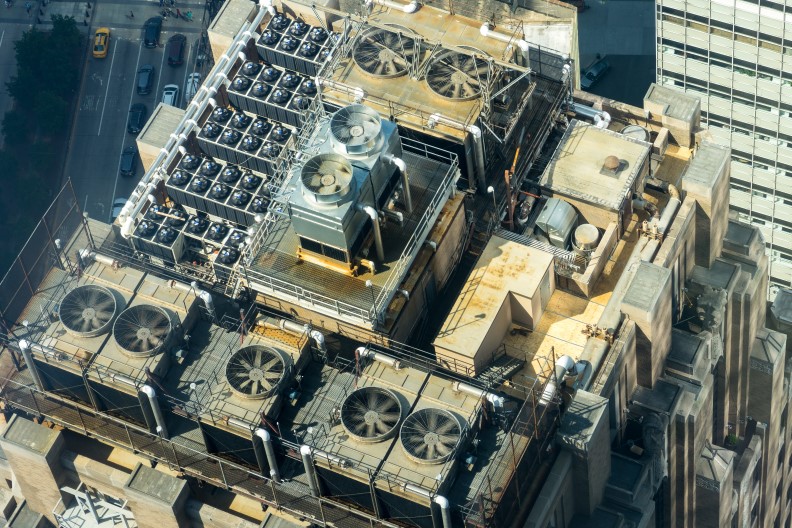

Air-handling units (AHU) have a very important role in HVAC installations, since they keep an adequate ventilation airflow for indoor areas. Air handlers have a much lower energy consumption than heating and cooling equipment, but their airflow determines the workload on the complete installation. If more outdoor air is being supplied by the air handler, the heating or cooling input must increase accordingly.

Since ventilation systems are fundamental for keeping adequate indoor conditions, ASHRAE has established stringent performance requirements for them. The main design reference for air-handling units is the ASHRAE Standard 62.1-2016: Ventilation for Acceptable Indoor Air Quality.

Basic Operation of Air-Handling Units

As their name implies, air-handling units are in charge of the air supply for indoor spaces. They keep the air in circulation, while providing the outdoor airflow required by design standards. However, using an AHU at full capacity all the time represents a waste of energy, since the occupant density is constantly changing.

The efficiency of air handlers can be greatly improved by adjusting airflow according to the number of occupants. This concept is called demand controlled ventilation or DCV, and it saves energy by avoiding an unnecessarily high air supply. However, the first step is ensuring that the ventilation system is suitable, since DCV can only be used with a variable air volume configuration (VAV). Constant air volume (CAV) systems are not suitable, for the simple reason that their airflow cannot be reduced.

A direct measurement of the number of persons in the building is challenging, since conventional occupancy sensors can only detect presence. In other words, they have the same response for one person or a crowd of 100 within their range. However, a carbon dioxide sensor provides a convenient solution, since the number of occupants correlates with the CO2 concentration.

DCV design has traditionally focused on occupancy, but making the system responsive to pollutant concentration is a promising concept. Consider that some activities release a large amount of air pollutants even with low occupancy – a key example is painting, which releases volatile organic compounds.

How DCV Saves Energy in Air-Handling Units

DCV achieves direct savings by reducing fan speed under partial occupancy. However, even greater savings are possible by reducing the workload on heating and cooling systems. Consider how an air handler interacts with other HVAC equipment:

- The heating or cooling input depends on the outdoor air (OA) temperature.

- Heating is needed when the OA temperature is below the set point, and cooling is needed when it is higher.

Since DCV reduces airflow based on occupancy, the energy required to reach the temperature set point is also reduced. For example, heating 1,000 cfm of air from 10°C to 20°C requires twice as much energy as heating 500 cfm.

Even if the heating and cooling systems have the highest efficiency in the market, they cannot perform at top efficiency if air handlers are always providing their maximum cfm. In larger buildings with multiple zones, also consider that individual savings from air handlers add up.

Related articles: